Glass ampoules are the most commonly used pharmaceutical packaging solution, with a current global volume of more than 30 billion. The handling of these ampoules, however, carry risk.

Ambulance paramedics at a Norwegian hospital, Martin Volden and Thomas Ulekleiv found themselves in stressful situations – in a moving vehicle or an emergency ward – every day. In particular, they were exposed to risks from withdrawing pharmaceuticals from the break-off glass ampoules: needle pricks; cuts from the razor-sharp edges of opened ampoules; spilling the valuable and hazardous contents; a high risk of mislabeling open ampoules; and contamination hazards.

-There is a massive operator and patient safety issue when the top is broken off these glass ampoules. Sharp glass edges are exposed, and the pharmaceutical content is exposed to air and other sources of contamination, Volden says.

The decontaminated environments of hospitals and ambulances are especially vulnerable to the spread of bacteria. From the moment an ampoule is broken open the likelihood of contamination increases rapidly.

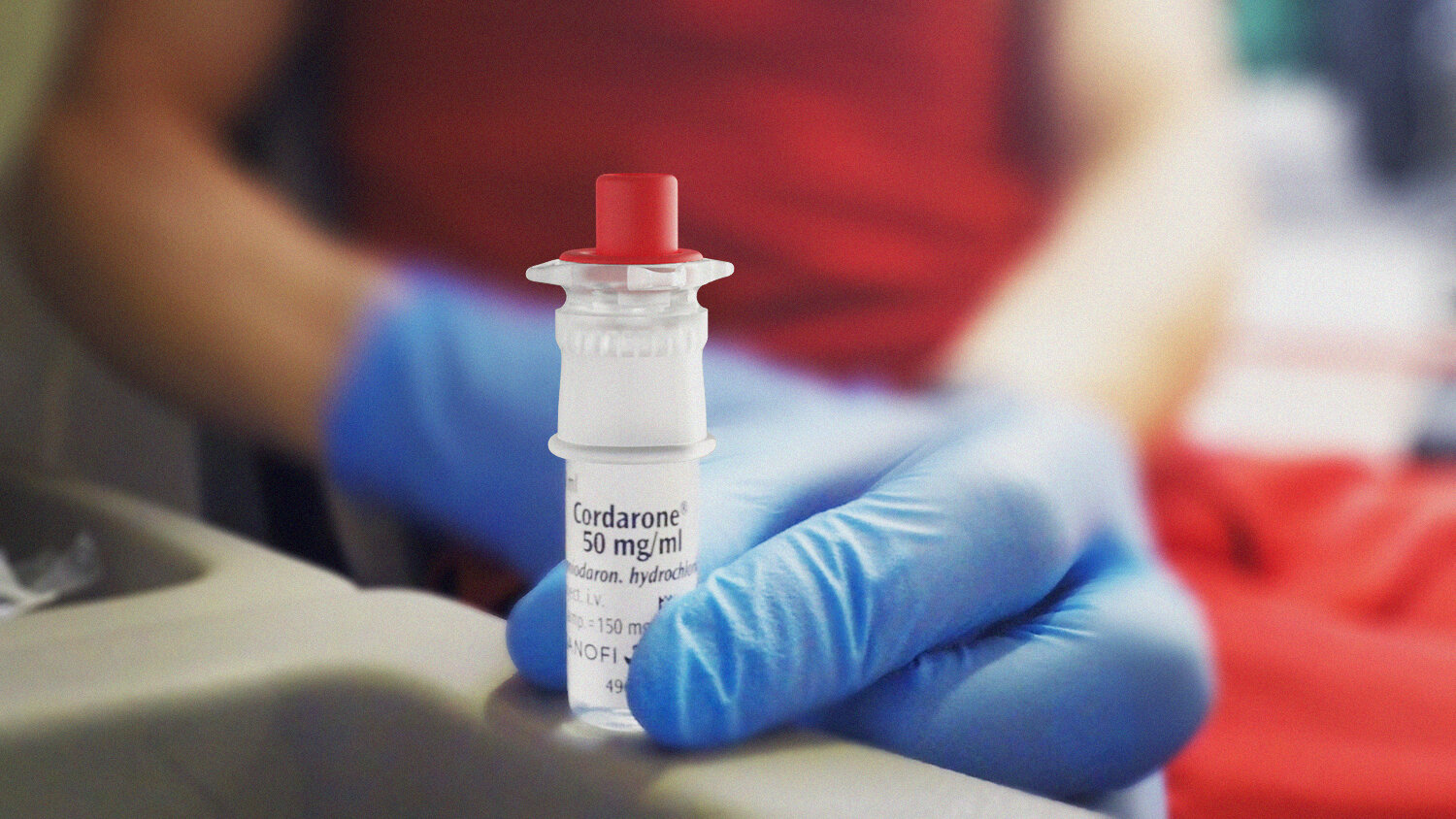

Volden and Ulekleiv approached product design agency K8 with the first prototype of AmpuSeal, a needle-free quick-connector between break-neck glass ampoules and the syringe. Together, they founded RabMed to develop a product that auto-mounts onto any glass ampoule with an irregular sharp edge, seals the open ampoule from outside exposure and protects users from cuts, reducing the risk of contamination by 50 percent.

Maneuvering the cost of testing

Before meeting the major B2B medical equipment suppliers that could take AmpuSeal to the global market, RabMed needed to test AmpuSeal vigorously with the target groups. This is normally a tall order for a startup.

-The cost of testing products at major medical facilities is prohibitive. As a startup, you normally need personal connections to get inside these institutions, says Marius Andresen, director of K8.

Nordic Proof is a non-profit organization that offers a network of professional testbeds that contribute to business development in the Nordic healthcare sector. They agreed to help RabMed conduct early-phase studies and testing through roundtable sessions with three testbeds: Danderyds Hospital in Stockholm, Oslo University Hospital Intervention Center and Oulu University Hospital in Finland.

-Nordic Proof opened an avenue to affordable testing in the Nordics, Andresen says.

Prior to the test sessions, the hospitals provided statistics for ampoule-related cuts and wounds; information on who establishes and introduces ampoule procedures; typical medications; ampoule sizes, etc. The sessions began with the AmpuSeal introduction video, before participants were allowed to test and discuss AmpuSeal. RabMed quickly learned how to draw the most relevant information from the sessions:

-We came in selling the product as if we were doing a sales pitch. We soon realized that the meetings were most valuable to us if we sat back and allowed them to be brutally honest – almost prompting their most critical feedback, Andresen says.

Each facility produced a detailed feedback report from the sessions.

Effect and next steps

Based on the feedback and preliminary meetings with a major international medical equipment supplier, RabMed was able to reduce production costs for AmpuSeal by 32 per cent, allowing them to present a much stronger market case:

-The feedback differed depending on the panel participants’ background. But it was always useful and helped us arrive at a level of product development where we could comfortably discuss production and pricing with the large B2B medtech device companies, Andresen says.

RABMED AS

Company country: Norway

Contact name: Marius Andresen

Contact phone: +47 93415461

Contact e-mail: [email protected]